Product Line

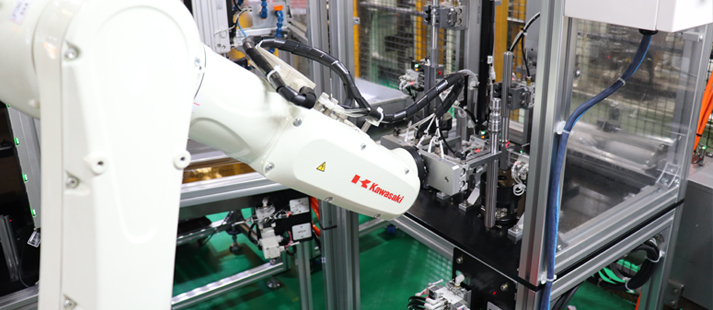

During the manufacturing of the parts until the assembly process, we utilize the automatic during these processes to ensure the effectiveness and maximize the production ability of the company.

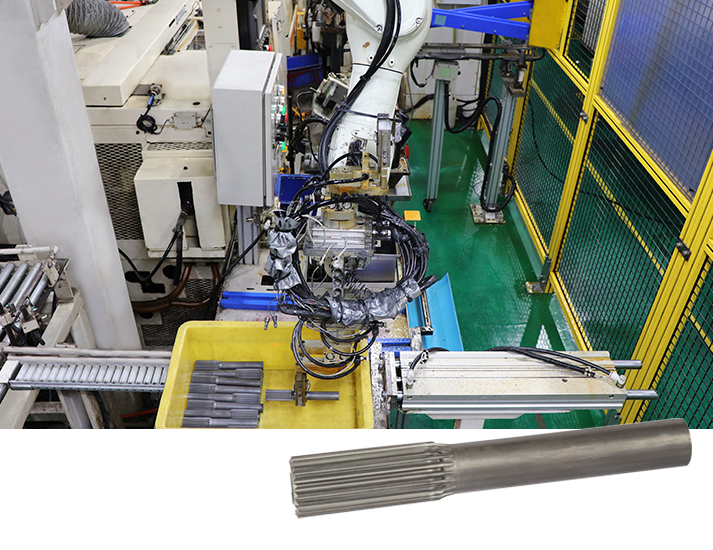

Sleeve continuous production line

As a result of the creation and design of hydraulic press from the parent company, the company's layout is improving in its effectivensess in terms of utilizing space.

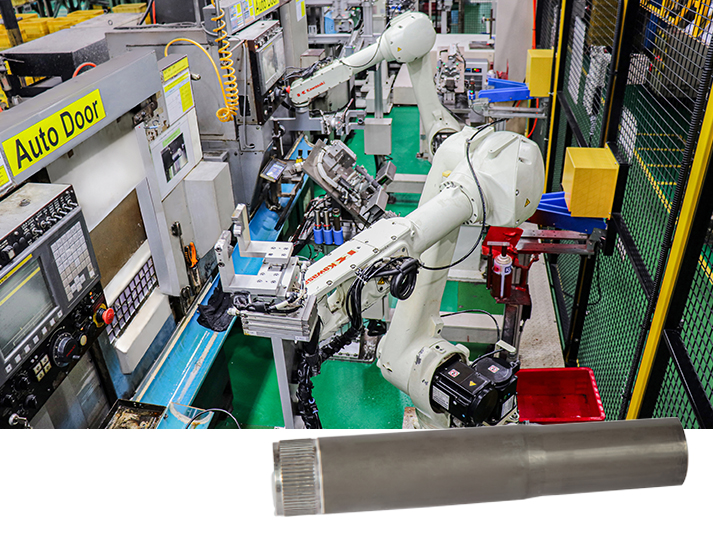

Shaft (Bar) continuous production line

The production line used to have 10 people for 2 shifts in the process of produce, dimension checking, appearance checking, and packing. We have successfully developed a fully automated system that eliminates the need for people in every process.

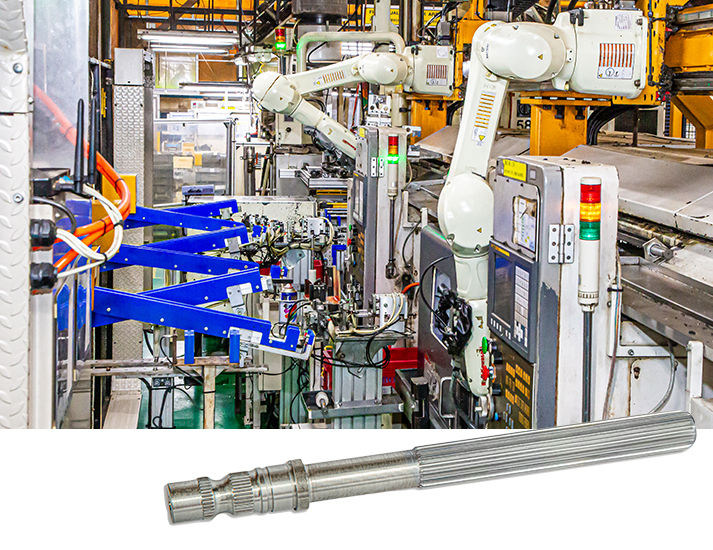

Shaft (Pipe) continuous production line

After the formation of Pipe, the production line will change to be continous production line since the CNC process, washing, until packing for the further process of the production such as high frequency hardening, grinding, rolling, welding, and assembly. In addition every production process perform the in-line quality assurance based on production quality quarantees principle